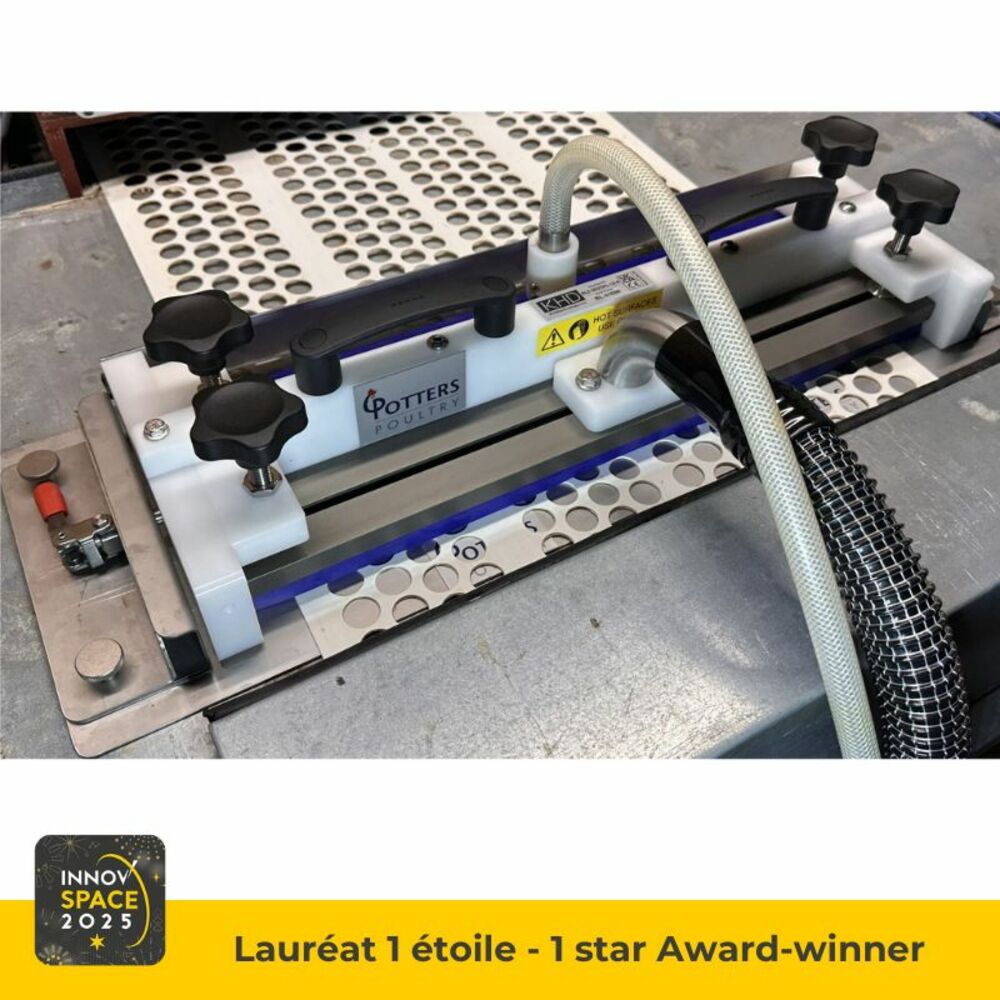

1 star Innov'Space award-winner

Portable dry steam solution for effective cleaning of hatching egg belts

This brand new leading edge application to the poultry industry was developed in the United Kingdom in Partnership between Potters Poultry & KHD Technology. The equipment currently has a patent pending specific to the Poultry Sector. It was derived from the need to reduce bacterial load on automatic nest box egg belts during the production cycle and maximise biological performance potential. AviSteam comprises a steam head, a steam generator and a vacuum. All three elements can be easily moved from one belt to another. Tap water is converted into high power dry steam using the portable generator. The dry steam is transferred via a hose to the steam head to make contact with the egg belt. It is a chemical free and highly efficient solution that uses as little as 10-20 litres of tap water per hour. Debris from the belt and moisture are sucked from the belt via the steam head with a vacuum.

- Dónde encontrarlo

- Hall 10 - C80